Sunday, 19 January 2025

DIY shed building made easy for newcomers

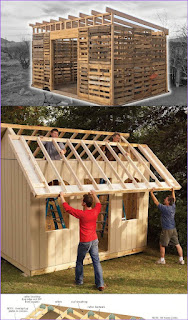

Constructing a DIY Shed: A Comprehensive Guide for Beginners

Building your own shed can be a rewarding and cost-effective project. This comprehensive guide provides a step-by-step approach, tailored for newcomers to shed construction. While requiring dedication and effort, the process is manageable with careful planning and adherence to safety protocols. This guide will equip you with the knowledge and confidence to successfully complete your shed project.

Phase 1: Planning and Preparation

Thorough planning forms the bedrock of a successful shed construction project. Insufficient planning often leads to costly errors and delays. This phase encompasses several crucial steps:

1.1 Determining Shed Specifications

Begin by defining your shed's purpose. Will it serve as storage for gardening tools, a workshop, or a combination of uses? This will dictate the required size, features, and materials. Consider factors such as:

- Dimensions: Length, width, and height. Draw a detailed sketch to scale.

- Materials: Wood, metal, or plastic? Wood offers versatility and aesthetic appeal, while metal is durable and low-maintenance. Plastic provides affordability and weather resistance.

- Features: Door type (single, double, sliding), windows (for ventilation and light), shelving, workbench, electrical wiring (if applicable).

- Budget: Establish a realistic budget, factoring in materials, tools, and potential unforeseen expenses.

1.2 Site Selection and Preparation

The chosen location significantly impacts the shed's longevity and usability. Consider the following:

- Accessibility: Ensure easy access for delivery of materials and future maintenance.

- Level Ground: A level base is critical for stability. Uneven ground necessitates leveling before foundation construction.

- Sunlight and Shade: Balance sun exposure for natural light with shade to prevent overheating.

- Drainage: Select a location with good drainage to prevent water accumulation and potential foundation damage.

- Local Regulations: Check local building codes and zoning regulations regarding shed size, placement, and permits.

Once the location is finalized, clear the area of vegetation, debris, and any obstructions. Level the ground using a shovel and rake, ensuring a firm, even surface.

1.3 Acquiring Necessary Tools and Materials

A comprehensive list of tools and materials is essential for efficient construction. This list may vary depending on the shed design and materials used. However, some common necessities include:

- Measuring Tape

- Level

- Shovel

- Post Hole Digger (if necessary)

- Hammer

- Screwdriver (various types)

- Drill

- Saw (circular saw or hand saw)

- Safety Glasses

- Work Gloves

- Wood Preservative (if using wood)

- Concrete Mix (for foundation)

- Building Materials (lumber, sheathing, roofing, etc.)

Before commencing construction, carefully review the material list and ensure all necessary items are readily available. Purchasing materials in advance minimizes delays during construction.

Phase 2: Foundation Construction

A sturdy foundation is crucial for a long-lasting shed. The appropriate foundation type depends on factors such as soil conditions and shed size. Common options include concrete slabs, gravel bases, and pier foundations.

2.1 Concrete Slab Foundation

This provides the most robust and stable foundation. It involves excavating a level area, creating a formwork, and pouring a concrete slab. Ensure the slab is level and allows for proper drainage.

2.2 Gravel Base Foundation

A simpler and more cost-effective option suitable for smaller sheds on well-drained soil. It involves laying a layer of compacted gravel to create a level base.

2.3 Pier Foundation

This method uses concrete piers or posts set into the ground to support the shed's frame. It’s suitable for uneven terrain but requires more precise measurements and leveling.

Regardless of the chosen foundation type, allow sufficient curing time before proceeding to the next phase. This ensures the foundation’s stability and prevents settling.

Phase 3: Frame Construction

Constructing the shed's frame involves assembling the walls and roof structure. Precise measurements and accurate cuts are paramount for a sturdy and aesthetically pleasing shed.

3.1 Wall Framing

Begin by constructing the wall frames according to your plan. Use pressure-treated lumber to resist rot and insect damage. Securely fasten the vertical studs to the horizontal plates using appropriate fasteners.

3.2 Roof Framing

The roof design (gable, hip, shed) impacts the framing process. Construct the roof trusses or rafters according to your design, ensuring they are properly aligned and securely fastened.

3.3 Frame Assembly

Once the wall and roof frames are complete, erect the walls and secure them to the foundation. Carefully lift and position the roof frame onto the walls, ensuring proper alignment and securing it with appropriate fasteners.

Phase 4: Sheathing, Roofing, and Finishing

This phase involves covering the frame with sheathing, installing the roofing material, and adding finishing touches.

4.1 Sheathing

Attach sheathing (plywood or OSB) to the exterior walls and roof to provide structural support and a surface for the siding and roofing materials.

4.2 Roofing

Install the roofing material (asphalt shingles, metal sheets, etc.) according to the manufacturer's instructions. Ensure proper overlap to prevent leaks.

4.3 Siding and Trim

Apply the chosen siding material (wood, vinyl, metal) and trim to enhance the shed's aesthetics and provide weather protection.

4.4 Doors and Windows

Install the doors and windows, ensuring proper fitting and weather sealing.

4.5 Interior Finishes

(Optional) Add interior finishes such as shelving, a workbench, or painting to customize the shed's interior.

Phase 5: Final Inspection and Clean Up

Conduct a final inspection to check for any imperfections or necessary repairs. Address any issues before declaring the project complete. Dispose of construction debris responsibly and clean the surrounding area.

Disclaimer: This guide provides general information. Always consult local building codes and seek professional advice when necessary. Safety should be your top priority. Use appropriate safety gear throughout the construction process.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.